Can you Sublimate on Vinyl? A Complete Guide

I’ll always go to bat for sublimation printing: it is a craft with so many intricacies and new ways to learn. As you develop your skill you can find all sorts of new ways to create your designs: from simply more varied designs to the more involved DTF transfers, and even through to the elusive question of whether you can sublimate on vinyl.

It’s elusive no longer: below I’ve detailed how to sublimate onto vinyl using a few methods, along with some useful tips on how to improve your process. I’ve tried to be as comprehensive as I can be, so read on to find out everything you need to know about vinyl sublimation!

How to Sublimate on Vinyl

Sublimating on vinyl isn’t too different from sublimating normally, but the type of vinyl used will determine the subtle differences in your process. There are many commercially available types of vinyl for crafting purposes. The most common vinyl materials are made of polyvinyl chloride (PVC), however this is generally unsuitable for sublimation printing due to its low-temperature tolerance.

Temperature control is crucial when working with different types of vinyl to avoid melting or damage during the pressing process. You need to use a heat transfer machine in order to finalize the design.

In a pinch, you can use an iron rather than a heat transfer machine for a budget-friendly sublimation setup. However, results will vary.

We frequently use HTV – or heat transfer vinyl – for sublimating on dark shirts or other dark materials. This can either work as a simply base layer for the heat transfer process, or directly onto the vinyl itself with compatible sublimation ink.

Use Clear Vinyl as a base and apply a thin layer of white ink before printing the sublimation design, which will give you better color clarity and vibrancy. Alternatively, use an HTV that is plain white or grey and impress your sublimation print onto it directly – though you should make sure to mirror (flip) your design before the heat press.

The other major method of sublimating with vinyl is using an Adhesive Vinyl: there are specialist polymer-coated adhesive vinyls that are highly compatible with sublimation printing. All you need to do is apply the sublimation print to the adhesive side, and put it in the heat press. However, these purpose-made vinyl rolls are more expensive than other formats, so be mindful of that when purchasing. I recommend a vinyl such as Siser EasyWeed, for the best balance of value and quality.

Sublimation on Vinyl – Things to Consider

Alongside the choice of vinyl that you’ll use, there are some other elements to consider when sublimating.

Temperature and Pressure

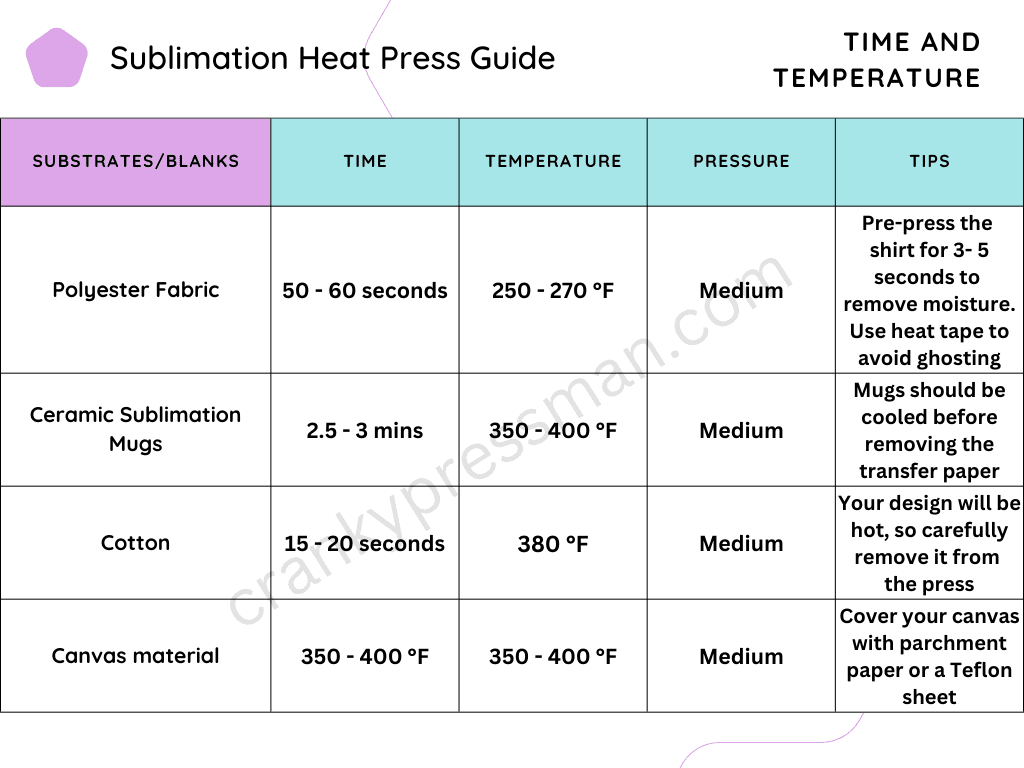

Getting the right heat press settings for vinyl sublimation is crucial: too hot and you’ll ruin the design, or too low-pressure and the transfer won’t take. Depending on what substrate you are pressing onto and what type of vinyl, the temperature and pressure settings can vary wildly.

Always use a protective layer such as parchment paper when sublimating, to avoid damaging the substrate.

Generally speaking, HTV vinyl should be set with 300-320°F, Medium pressure settings, for between 10 and 20 seconds. Be sure to check with the vinyl manufacturer for the best results.

Here are some helpful guidelines for temperature that you can use depending on your choice of substrate.

Sublimation Print Settings

As mentioned, you can use vinyl as a base layer to get more detailed or vibrant designs, which can be useful if you’re struggling to make sublimation brighter. You can also find specific ICC color profiles for your printer that help to boost the design’s color gamut. These can help boost your design when printing for better results.

Sublimation Printer

As I’ve mentioned many times on this page, sublimation printing is an accessible art, with a range of printers across a range of budgets to suit different needs. You can even convert printers for sublimation, if they’re compatible, but there is a ceiling to the quality of results.

If you are just a beginner sublimation printer, it’s understandable why you don’t want to invest too heavily in your hobby. However, it may be time to upgrade your printer if you are looking to get the best results when sublimating with vinyl.

Sublimation Ink

Similarly, there are certain sublimation inks that are better suited to use with vinyl, for long-lasting and vibrant prints. Sublimation ink is specially formulated to infuse polyester fibers, so it’s important to ensure that the ink you choose matches your vinyl material.

I generally recommend Hiipoo ink sets, for their range of compatibility and overall great value for money. That said, it’s also important to consider factors like cost and availability yourself, as like with printers there is not a “best” for every situation.

Sublimation on Vinyl – Potential Issues

It’s important to be aware of the issues you will likely face when sublimating on vinyl. I’ve listed them here, along with how to solve them:

Bleeding

One of the most common issues people face when they try to sublimate on vinyl is bleeding. This problem occurs when the colors from the design transfer onto the vinyl’s adhesive layer, creating a blurry or messy appearance.

The result is often something that looks like a bad tie-dye job. This issue usually happens because of inadequate heat and pressure or low-quality vinyl.

To avoid bleeding, it’s essential to ensure that your heat press is operating at the correct temperature and pressure. In addition, you may need to adjust your transfer paper’s timing and/or use high-quality vinyl that can withstand high temperatures.

Melting

When you expose certain types of thin or poorly made vinyl to high temperatures for an extended period of time, it may melt or distort. This issue can ruin your project and even damage your equipment.

To avoid melting, make sure you’re using a quality vinyl that’s recommended for sublimation purposes, such as Siser EasySubli HTV or Forever Subli-Flex 202. Additionally, always double-check to ensure that your heat press isn’t set too hot before applying any vinyl material.

Desaturation

It’s not uncommon to find your sublimated designs appearing washed-out or faded in the end result. This can have a number of root causes, but one I encounter frequently with vinyl is a surplus of moisture in the target substrate.

This is fairly easy to fix, however, and should be a part of your routine pre-sublimation regardless. Try ironing the target substrate to remove creases and wrinkles, then leave it to dry somewhere warm before sublimation.

Though this is a cause, desaturation or fading can be caused by a number of issues such as clogged printheads or poor image quality. Check out our guide on how to make sublimation brighter for a comprehensive breakdown of issues.

Burning/Browning

It can be hard to know when your design has finished its heat press process, especially when you can’t see it in the machine. If your results are coming our browned or even charred, then the root problem lies with your heat press machine.

Make sure that you’ve got the temperature correctly set, along with the pressure configuration. Finally, don’t leave the design in there longer than the allotted time slot.

FAQs:

100% polyester fabrics are the best for sublimating onto t-shirts or other clothing, for the most flaw-free transference of the design. However, supplementing in a blend of cotton or vinyl can create unique results such as a vintage washed-out effect.

You can design sublimation prints on any graphic design or art software, provided you can export it to a compatible format. I use Adobe Photoshop and Illustrator for my work, but Canva or even native design software like Cricut’s Design Space give you plenty of options. For some inspiration, check out these free sublimation designs!

Final Word

Learning how to sublimate on vinyl is a good skill to have, giving you access to a range of options to improve and alter your sublimation prints. I hope you take forward what I’ve shown you today, and get even better results from your custom print process.

For all the best advice on sublimation and its subcategories – from printers to paper – I’ll keep you posted here at The Cranky Press Man!