Sublimation Vs. Heat Transfer Vinyl

DIY craft is a mushrooming industry; custom prints will always stay in vogue. However, when I began planning out my DIY craft business, I came across multiple choices. These included sublimation printing and heat transfer vinyl, the two widely known custom DIY design solutions.

But which one to choose? Is sublimation printing cheaper than heat transfer vinyl? Which has better output? Whose designs will last longer?

I, too, had all these questions before deciding which printing method to choose. But don’t fret! Your decision-making woes end here.

I will shed light on these design methods and list the differences, the materials involved, and the overall cost of starting out. Let’s begin.

What is Sublimation?

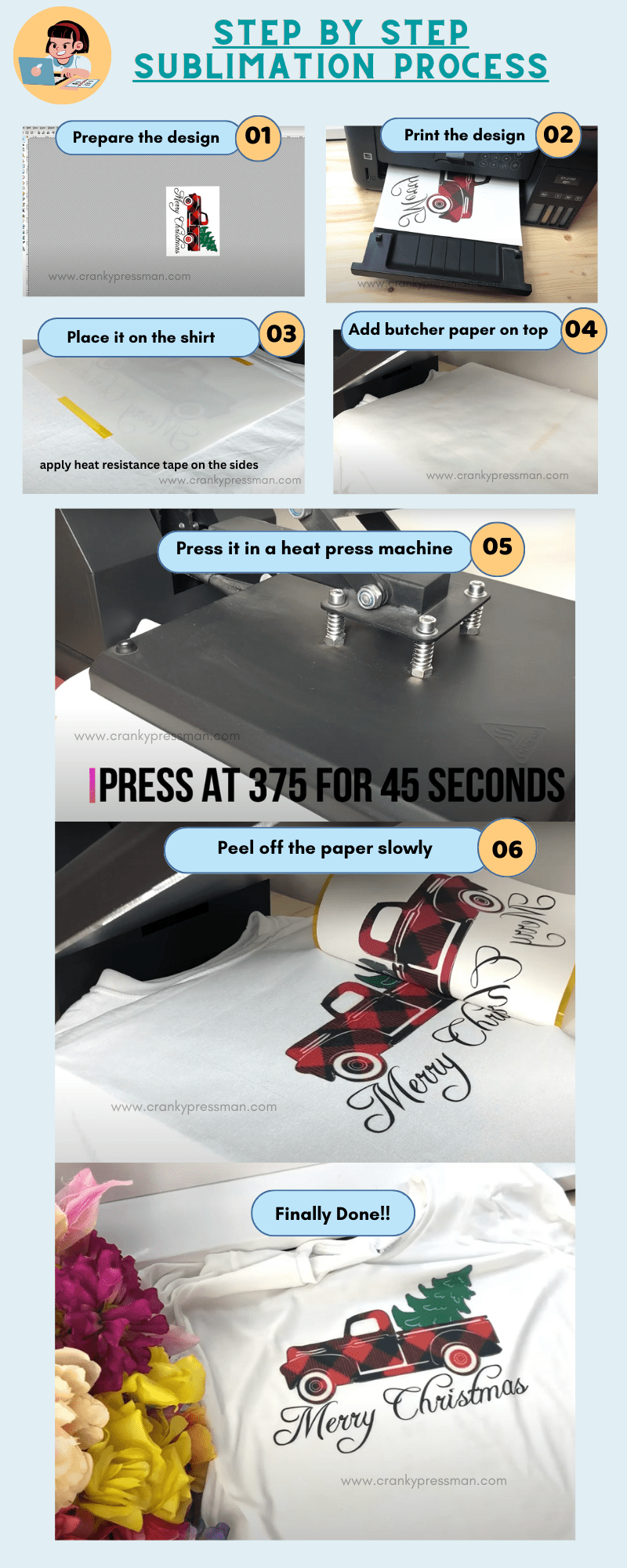

Sublimation involves transferring the design from a special paper called a sublimation paper with the help of a heat press. You need a special kind of paper and ink and a good sublimation printer. Moreover, you can convert some specific printer models into sublimation printers easily.

The paper is an excellent ink absorbent. The ink binds well when you put the paper in direct contact with the fabric or any other befitting substrate.

What is Heat Transfer Vinyl?

Heat Transfer Vinyl requires a different approach than sublimation. You don’t print anything but cut the designs on the vinyl sheet. It requires a vinyl sheet cutter that can cut designs (even complex logos and art). After that, the process is somewhat similar to sublimation. You place the design on the target material and then use the heat press to transfer it.

Now, you know the basics of both techniques. Let’s now compare both of them to various factors:

Material Required

Sublimation printing needs a sublimation printer, sublimation paper, sublimation ink, heat press, and heat-resistant tape.

Heat transfer vinyl requires a special cutting machine and companion software to make precision trimmings. In addition, you also need a heat press to transfer the design to the fabric or other target materials.

So, sublimation printing requires a more extensive item inventory than heat transfer vinyl. You also have to occasionally replace the ink and paper, which adds to the overall materials required to run a sublimation printing business.

Startup Cost

It is clear that sublimation printing involves many more items to print a design on the fabric or any other substrate. Moreover, there is a recurring cost of sublimation ink and paper, which aren’t cheap.

Related: read our guide on the best sublimation printers of the year right here.

Depending on the features, you need a sublimation printer (original or converted) that retails for $500 or upwards. You can save money using a converted printer, which costs $200-$300. Then, a pack of sublimation paper costs $20-$30, and the ink will also cost the same. So, you are considering an initial investment of $500-$600, excluding the heat press.

In heat transfer vinyl, you need a design cutter machine that starts from $300. The heat transfer vinyl sheet comes in both rolls and sheets, and the cost is comparable to the sublimation paper.

But you don’t need ink in heat transfer vinyl because you etch the vinyl on the fabric. Heat press costs about the same so we won’t factor it in here.

Clearly, sublimation printing is a slightly expensive endeavor because of the recurring cost of ink and paper.

Print Quality

Sublimation printing can produce vivid color output in multi-color format. You can print any design with a complex color palette without any doubt. Moreover, sublimation ink binds well with polyester and a few other substrates and appears as part of the fabric.

You are mostly confined to single or dual-color designs in heat transfer vinyl. It is possible to print multi-color designs, but that requires a very elaborate process, and it is exhausting because you are printing a single design. Since vinyl latches onto the fabric, you will feel its thickness when you run your finger through it. Heat transfer vinyl doesn’t combine with the substrate and only attaches to it.

You can print photorealistic designs using sublimation and quickly transfer them on the substrate without losing quality. However, you cannot print photorealistic designs using heat transfer vinyl because it is mainly suited to simple artwork designs.

There is a special kind of paper that you can use to print and then use a transfer sheet, but that is quite laborious when you compare it with sublimation printing.

So, sublimation printing offers superior print quality and supports multi-color photo realistic images. But heat transfer vinyl is suitable for simple logos and designs with a single solid color.

Printing Process

Sublimation printing requires more materials to set up the shop, but the process is quite simple. Once you get the color output and ink right, you only need to upload a design, print it, and press it directly on the fabric. That’s all. You don’t need to do more.

Heat transfer vinyl might sound even less laborious, but that isn’t the case with complex designs. After you upload the design and give the cutting command to the cutter machine, you cannot directly press the design on the fabric. You must peel off the excess vinyl from the design bit by bit. Only the outline is easy to remove, but other intricate areas of design require more effort. So, it isn’t precisely a cut-and-press process as it appears.

Types Of Materials

Sublimation binds exceptionally well with polyester. However, it has trouble binding with other natural fibers and needs some percentage of the polyester in the target fabric. However, there are workarounds for this: one involves using a laminate sheet or a sublimation spray. One more pain point with sublimation is that it works better with light-colored fabrics.

Heat transfer vinyl works with all fabrics and surfaces, including metal, hardboard, and plywood. So, you can work on a wide range of materials and offer design and customization services. Moreover, you don’t need to stick to light-colored fabrics because heat transfer vinyl works with light and dark-colored fabrics.

Design Longevity

Sublimation printing etches the sublimation ink on the substrate. The result feels almost like the design is part of the fabric. It doesn’t peel off or fade away after a few washes and thus lasts longer. But you still need to take care of the fabric and avoid harsh and frequent wash cycles.

Heat press vinyl has a shorter lifespan simply because it is attached to the fabric. It starts to crack and peel off with time. However, it will still last longer if you handle it carefully and avoid using bleach.

Verdict

Sublimation printing and heat vinyl transfer have their pros and cons. I cannot just promote one and discard the other because both have their use cases.

If you want to put logos and single/dual color designs on various materials(both light and dark colored), heat transfer vinyl won’t disappoint you. However, you will have to put some effort into peeling the non-useful vinyl off the design. My advice will be to use designs that are a single piece and do not contain too much fine artistry (or it will be a pain to peel off).

Go for sublimation printing to print photorealistic designs on different materials. You won’t have to peel off anything from the design. Just cut it (if necessary) and place it on the substrate in a heat press. However, inks and paper costs will be slightly high, and you won’t be able to sublimate cotton or other natural fabrics and dark-colored items.